Area For Calcium Carbonate Crusher Dimension Plant

Carbon mineralization pathways for carbon capture,

2021年2月26日CO 2 generated from power plants or industrial sources can Calcium carbonate is heated at 900–950 °C to produce pure CO 2 and with high surface area particles and sizes in the range

11.19.2 Crushed Stone Processing and Pulverized

bins, to open area stock piles, or to other processing systems such as washing, air

Customize Suitable Calcium Carbonate Plant DASWELL

Calcium Carbonate Processing Plant Processing materials: Limestone, calcite,

11.17 Lime Manufacturing US EPA

crushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating;

4 Steps to Build a Calcium Carbonate Processing Plant

2022年9月29日The commonly used calcium carbonate fineness is 0-3mm, 80

Hammermill Crushers McLanahan

The Standard and Non-Clog Hammermills are considered primary crushers, with some

Limestone and Crushed Rock Energy

In 1978, the National Stone Association reported that out of 20 plants surveyed energy

Particle size and surface area of calcium carbonate powder.

The adsorption peaks of the limestone at 713 cm −1,875 cm −1 and the band between

11.19.2 Crushed Stone Processing and Pulverized Mineral

bins, to open area stock piles, or to other processing systems such as washing, air separators, and screens and classifiers (for the production of manufactured sand). Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th inch). Crushed stone from the tertiary

Daswell Ground Calcium Carbonate Process CaCO₃ Plant

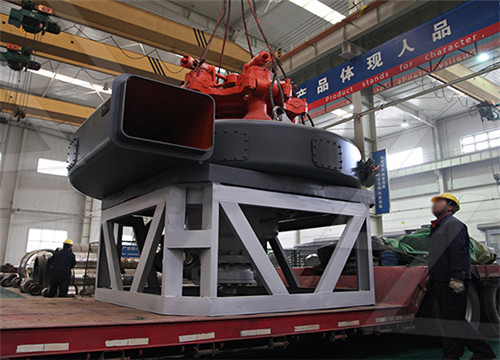

The whole ground calcium carbonate production process consist of crushing, grinding and coating. After the raw material is quarried, the limestone or marble is crushed to smaller sizes. And then these crushed limestone or marble is cleaned and classified to ensure the quality of end product.

11.17 Lime Manufacturing US EPA

crushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating; and (5) miscellaneous transfer, storage, and handling operations. A generalized material flow diagram for a lime manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants.

Aqueous Crystal Growth and Dissolution Kinetics of Calcium Carbonate

2018年4月2日Measurements of single crystals at the ADRS Grid Area include: weight and dimension changes, repeat macro photography, and Environmental Scanning Electron Microscopy (ESEM). On-site measurements of calcium carbonate single crystals (surrogates for soil carbonate crusts) at two grid locations assess carbonate mineral

4 Steps to Build a Calcium Carbonate Processing Plant

2022年9月29日The commonly used calcium carbonate fineness is 0-3mm, 80-425mesh and 25-3000mesh. 80-425mesh heavy calcium powder grinding mill For processing heavy calcium powder in the range of 80-425 mesh fineness, European mills and vertical roller mills can be selected. 1. European version grinding mill

Calcium Carbonate (Limestone) Mosaic Crop Nutrition

Calcium carbonate, the chief component of limestone, is a widely used amendment to neutralize soil acidity and to supply calcium (Ca) for plant nutrition. The term “lime” can refer to several products, but for agricultural use it

Effect of drying-wetting cycles on pore characteristics and

2023年3月9日This suggests that the D-W cycle erodes the calcium carbonate in the outer part in the first few cycles. Under this condition, the weight loss and reduction of CCC in the internal structure are relatively low. The CCC of the inner and middle parts will significantly reduce after a large amount of calcium carbonate is washed with distilled

Calcium Carbonate Grinding Process Mining, Crushing,

2013年5月9日2.Calcium carbonate milling equipment is easy to operate and maintain. 3.Production can meet the needs of the calcium carbonate processing equipment unit time. 4.Calcium carbonate milling equipment must also meet the needs of environmental protection. ? Limestone Crushing Production Line. Iron ore processing and mineral

Hardness of Water U.S. Geological Survey

2018年6月11日General guidelines for classification of waters are: 0 to 60 mg/L (milligrams per liter) as calcium carbonate is classified as soft; 61 to 120 mg/L as moderately hard; 121 to 180 mg/L as hard; and more than 180 mg/L as very hard. Sources/Usage: Some content may have restrictions. Visit Media to see details. Lime scale buildup inside a water pipe.

calcium carbonate crusher MiningQuarry Plant

2013年4月26日Calcium carbonate production method. Because of these 2 functions, the vibration and pressure, the block created by this machine may be stacked immediately when

calcium carbónate production plant github

calcium carbónate production plant (PDF) A Study for Enhancing Yield of Caustic Soda in Causticization. caustic production has become preferred process.balancing the demand on a

Calcareous Wikipedia

Calcareous sediments are usually deposited in shallow water near land, since the carbonate is precipitated by marine organisms that need land-derived nutrients. Generally speaking, the farther from land sediments fall, the less calcareous they are. Some areas can have interbedded calcareous sediments due to storms, or changes in ocean currents.

Calcium Carbonate an overview ScienceDirect Topics

The depth at which solution of calcium carbonate is complete is reached off western Africa coast (about 10° and 25°N) The solution distribution in the South Atlantic is largely as in Fig. 8. Percentage of calcium carbonate in modern sediments with contours of 25%, 50%, and 75% lined areas denote more than 50% (compiled by Emery and Uchupi

Calcium Carbonate Powder Plant HLMX Superfine Vertical Mill

HLMX type superfine vertical mill can be used as calcium carbonate milling plant is used to grind calcium carbonate, which can produce 1250 mesh fineness. Calcium carbonate powder production line equipment configuration: calcium carbonate crusher, elevator, electromagnetic vibrating feeder (with iron remover), calcium carbonate powder

11.19.2 Crushed Stone Processing and Pulverized Mineral

bins, to open area stock piles, or to other processing systems such as washing, air separators, and screens and classifiers (for the production of manufactured sand). Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th inch). Crushed stone from the tertiary

Daswell Ground Calcium Carbonate Process CaCO₃ Plant

The whole ground calcium carbonate production process consist of crushing, grinding and coating. After the raw material is quarried, the limestone or marble is crushed to smaller sizes. And then these crushed limestone or marble is cleaned and classified to ensure the quality of end product.

Aqueous Crystal Growth and Dissolution Kinetics of Calcium Carbonate

2018年4月2日Measurements of single crystals at the ADRS Grid Area include: weight and dimension changes, repeat macro photography, and Environmental Scanning Electron Microscopy (ESEM). On-site measurements of calcium carbonate single crystals (surrogates for soil carbonate crusts) at two grid locations assess carbonate mineral

Calcium Carbonate (Limestone) Mosaic Crop Nutrition

Calcium carbonate, the chief component of limestone, is a widely used amendment to neutralize soil acidity and to supply calcium (Ca) for plant nutrition. The term “lime” can refer to several products, but for agricultural use it

sbm/sbm calcium carbonate plant layout diagram.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Effect of drying-wetting cycles on pore characteristics and

2023年3月9日This suggests that the D-W cycle erodes the calcium carbonate in the outer part in the first few cycles. Under this condition, the weight loss and reduction of CCC in the internal structure are relatively low. The CCC of the inner and middle parts will significantly reduce after a large amount of calcium carbonate is washed with distilled

Calcium Carbonate Grinding Process Mining, Crushing,

2013年5月9日Calcium carbonate is a compound, Calcium carbonate is a raw material commonly used in the industrial production, the use of calcium carbonate in industry is mainly manifested in the following industries, such as the PVC industry,rubber industry, industry, it can be used as additives in the smelting industry.

calcium carbonate crusher MiningQuarry Plant

2013年4月26日Calcium carbonate production method. Because of these 2 functions, the vibration and pressure, the block created by this machine may be stacked immediately when

crusher/sbm purpose of calcium carbonate to plant.md at main

Contribute to yunan88/crusher development by creating an account on GitHub.

Calcium Carbonate Powder Plant HLMX Superfine Vertical Mill

HLMX type superfine vertical mill can be used as calcium carbonate milling plant is used to grind calcium carbonate, which can produce 1250 mesh fineness. Calcium carbonate powder production line equipment configuration: calcium carbonate crusher, elevator, electromagnetic vibrating feeder (with iron remover), calcium carbonate powder

Calcium Carbonate an overview ScienceDirect Topics

The depth at which solution of calcium carbonate is complete is reached off western Africa coast (about 10° and 25°N) The solution distribution in the South Atlantic is largely as in Fig. 8. Percentage of calcium carbonate in modern sediments with contours of 25%, 50%, and 75% lined areas denote more than 50% (compiled by Emery and Uchupi

Comparative effects of a novel plant-based calcium supplement PubMed

AC treatment significantly reduced the H(2)O(2)-induced oxidative stress when compared to calcium carbonate or calcium citrate (1.5- and 1.4-fold, respectively). These findings suggest that AC may serve as a superior calcium supplement as compared to other calcium salts tested in the present study.

precipitated calcium carbonate plant process flow chart

2013年8月28日The process is regulated by the plant hormone abscisic acid. Posts Related to process flow of precipitated calcium carbonate plant. mining company in tanzania;

Ball Mill System with Classifier for Producing Calcium Carbonate

2019年6月17日Quality equipment for calcium carbonate plant can be operated in time and guarantee the contractual capacity. The ball mill and classifier system for grinding calcium carbonate is an investment for 20 and 30 years rather than several years. Daswell will offer turnkey solutions for calcium carbonate plant according to customers’