Zinc Ingot Originates From Ore Dressing

Zinc processing Britannica

Brass, an alloy of copper and zinc, was produced by the Romans as early as 200 bce by heating copper, zinc oxide (ZnO), and carbon together. The zinc formed by the reduction of its oxide was absorbed into the copper

Zinc Geoscience Australia

IntroductionPropertiesUsesHistoryFormationResourcesMiningProcessing

Zinc (Zn) was used in Rome and China more than 2000 years ago as a component of brass which is a zinc-copper alloy. The Romans and Chinese smelted zinc ores such as calamine (zinc carbonate) with copper to produce brass, used for coins, containers, armour and jewellery. They did not actually realise that zinc was a metal. The Romans also used calam...

Zinc Ingot AMERICAN ELEMENTS

Zinc was first isolated by Andreas Marggraf in 1746. In its elemental form, zinc has a silver-gray appearance. It is brittle at ordinary temperatures but malleable at 100 °C to 150 °C.

Zinc: smelting, producing and classification-Metalpedia

Approximately 30% of all zinc produced is from recycled sources. There are two methods of smelting zinc: the pyrometallurgical process and the hydrometallurgical process (over

Zinc Ore an overview ScienceDirect Topics

Zinc oxide is prepared commercially by two methods: the American (or direct) process, which uses zinc ore and concentrate, and the French (or indirect) process, which uses

(PDF) Industry of Zinc Processing ResearchGate

2015年11月3日Dalam memproses zinc ore menjadi konsentrat, setelah dilakukan ore dressing dengan jaw chrusher dan juga ballmill machine,selanjutnya adalah me mprosesbya secara froth flotation.

Domestic Zinc Ore Supply Will Be Tight Throughout 2022,

2022年6月15日It remains to be seen whether the overseas market is able to fully digest zinc ingots expected from China so as to keep LME zinc inventories at a low level. LME

What is zinc ingots? Where can I get zinc ingots? A PLUS

2021年7月13日To date, the oldest evidence of pure zinc comes from Zawar, in Rajasthan, as early as the 9th century AD when a distillation process was employed to make pure zinc. Alchemists burned zinc in air

Oxide Metal :Zinc ingot smelting company buy Zinc

Zinc smelting is the process of converting zinc concentrates (zinc ash/ore /zinc powder) into zinc ingot. We request to buy Zinc concentrates and zinc Ore for Zinc smelting purpose, with Zn 20%-70% or above. Serious

Zinc Ore an overview ScienceDirect Topics

Zinc oxide is prepared commercially by two methods: the American (or direct) process, which uses zinc ore and concentrate, and the French (or indirect) process, which uses zinc metal. Some 54% of US zinc oxide production is from zinc ore and concentrate (American process), 33% from slab zinc (French process) and 13% from secondary material.

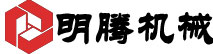

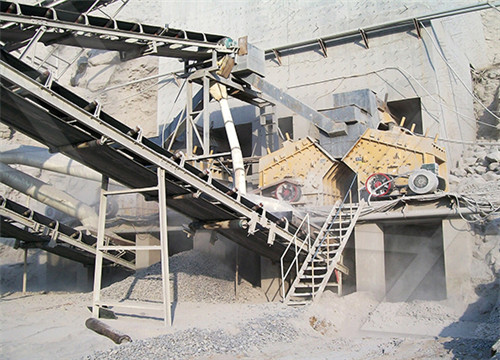

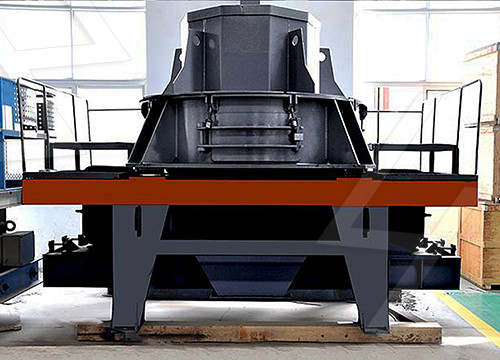

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable

Zinc: smelting, producing and classification-Metalpedia

Zinc is found in the earth’s crust primarily as zinc sulfide (ZnS). Rarely is the ore, as mined, rich enough to be used directly by smelters; it needs to be concentrated. Zinc ores contain 5-15% zinc. To concentrate the ore, it is first crushed and then ground to enable optimal separation from the other minerals.

Zinc Hydrometallurgy Metalcess

About 80% of the world’s copper-from-ore originates in Cu-Fe-S ores, such as chalcopyrite (CuFeS2) and chalcocite (Cu2S). The concentration of these minerals in an ore body is low. zinc sulfide ore/concentrate to produce zinc cathode, LME zinc ingot and zinc oxide powder. Zinc Pressure Leaching (ZPL) Zinc pressure leaching (ZPL) treats

Domestic Zinc Ore Supply Will Be Tight Throughout 2022,

2022年6月15日LME zinc inventory saw a slight increase recently due to the delivery of Chinese zinc ingots in Kaohsiung and other regions. It remains to be seen whether the overseas market is able to fully digest zinc ingots expected from China so as to keep LME zinc inventories at a low level. LME zinc prices are expected to fluctuate at a high level.

Ore Mining and Dressing Effluent Guidelines US EPA

2021年7月10日EPA promulgated the Ore Mining and Dressing Effluent Guidelines and Standards (40 CFR Part 440) in 1975, and amended the regulation in 1978, 1979, 1982 and 1988. The regulation covers

SMM: Short Supply of Zinc Ore Likely to Ease by 2023

2021年12月10日Recovery of domestic zinc ore output was slow due to COVID and dropped grade . SMM expects that the increase in zinc ingot production can reach about 200,000 mt. Production progress of domestic smelters . According to SMM statistics on the commissioning of domestic smelters, the total production capacity of hot-dip galvanised

Oxide Metal :Zinc ingot smelting company buy Zinc

About Oxide Metal. We produce remelted zinc ingots for galvanizing and brass industries. Our annual capacity of production zinc ingots is around 550,000 tons/year. We market zinc and lead not only from our own

Turkish Metal :Zinc ingot smelting company buy Zinc Ore,Zinc

We produce remelted zinc ingots for galvanizing and brass industries. Our annual capacity of production zinc ingots is around 550,000 tons/year. Zinc smelting is the process of converting zinc concentrates (zinc ash/ore /zinc powder) into zinc ingot. We request to buy Zinc concentrates and zinc Ore for Zinc smelting purpose, with Zn 20%-70%

Zinc IngotsOre Kibali Gold Mine

Zinc ingotsOre. Kibali Gold Mine supplies and exports Zinc ingots, as well as alloy, granule etc from Africa. For years, we strive to provide our clients with the high quality products and at the best global market rates. Specifications. Type: Zinc Bar Zn (Min): 99.999% Alloy Or Not: Non-alloy

Kumtal :Zinc ingot smelting company buy Zinc Ore,Zinc

2020年3月28日Zinc smelting is the process of converting zinc concentrates into zinc ingot. We request to buy Zinc concentrates and zinc Ore for Zinc smelting purpose, with Zn 20%-70% or above. Messages. Many of our suppliers have a long standing relationship with Kumtal, leading to benefits such as technical support.

Zinc Ingot Spiritfarer Wiki Fandom

Zinc Ingots are made at a Foundry from Zinc Ore, which can be found at the following locations: 2 nodes at Southpoint Docks 1 node at Hidden Thicket 3 nodes at Flotsam Shores Usage Construction/Improvement at Blueprint Station Crafting at Smithy Boat Upgrades at Albert's Shipyard Categories

Zinc Ingot Slimefun/Slimefun4 Wiki GitHub

Slimefun 4 A unique Spigot/Paper plugin that looks and feels like a modpack. We've been giving you backpacks, jetpacks, reactors and much more since 2013. Zinc Ingot Slimefun/Slimefun4 Wiki

Solution Yantai Jinpeng Mining equipment, ore dressing process

It is an old cyanidation process. Firstly, add cyanide into ore to leach out minerals, then separate the solid and liquid. Add zinc powder or zinc wire into the liquid and the gold and silver will settle as gold mud via chemical reaction. The gold mud containing high gold and silver will be re-smelted to high-pure gold ingot. At present, this process as the

Flotation ore dressing Britannica

flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water. The flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. [1] Depending on the processes used in each instance, it is often also known as ore dressing or ore milling .

Zinc Ore an overview ScienceDirect Topics

Zinc oxide is prepared commercially by two methods: the American (or direct) process, which uses zinc ore and concentrate, and the French (or indirect) process, which uses zinc metal. Some 54% of US zinc oxide production is from zinc ore and concentrate (American process), 33% from slab zinc (French process) and 13% from secondary material.

Zinc Hydrometallurgy Metalcess

About 80% of the world’s copper-from-ore originates in Cu-Fe-S ores, such as chalcopyrite (CuFeS2) and chalcocite (Cu2S). The concentration of these minerals in an ore body is low. zinc sulfide ore/concentrate to produce zinc cathode, LME zinc ingot and zinc oxide powder. Zinc Pressure Leaching (ZPL) Zinc pressure leaching (ZPL) treats

Domestic Zinc Ore Supply Will Be Tight Throughout 2022,

2022年6月15日LME zinc inventory saw a slight increase recently due to the delivery of Chinese zinc ingots in Kaohsiung and other regions. It remains to be seen whether the overseas market is able to fully digest zinc ingots expected from China so as to keep LME zinc inventories at a low level. LME zinc prices are expected to fluctuate at a high level.

Ore Mining and Dressing Effluent Guidelines US EPA

2021年7月10日EPA promulgated the Ore Mining and Dressing Effluent Guidelines and Standards (40 CFR Part 440) in 1975, and amended the regulation in 1978, 1979, 1982 and 1988. The regulation covers wastewater discharges from ore mines and processing operations. The Ore Mining Effluent Guidelines and Standards are incorporated into

Oxide Metal :Zinc ingot smelting company buy Zinc Ore,Zinc

We produce remelted zinc ingots and We are looking for Zinc Ash/Ore Zinc and Lead Mines We buy for our factory (smelter) on annual basis Zinc ore 20% 40% and 30% 60% concentrate, from all countries Zinc Ingot Sales Zinc Ingot has been produced between 99.96–99.99 percent in our Company.

Kumtal :Zinc ingot smelting company buy Zinc Ore,Zinc

2020年3月28日Zinc smelting is the process of converting zinc concentrates into zinc ingot. We request to buy Zinc concentrates and zinc Ore for Zinc smelting purpose, with Zn 20%-70% or above. Messages. Many of our suppliers have a long standing relationship with Kumtal, leading to benefits such as technical support.

Turkish Metal :Zinc ingot smelting company buy Zinc Ore,Zinc

We produce remelted zinc ingots for galvanizing and brass industries. Our annual capacity of production zinc ingots is around 550,000 tons/year. Zinc smelting is the process of converting zinc concentrates (zinc ash/ore /zinc powder) into zinc ingot. We request to buy Zinc concentrates and zinc Ore for Zinc smelting purpose, with Zn 20%-70%

Zinc IngotsOre Kibali Gold Mine

Zinc ingotsOre. Kibali Gold Mine supplies and exports Zinc ingots, as well as alloy, granule etc from Africa. For years, we strive to provide our clients with the high quality products and at the best global market rates. Specifications. Type: Zinc Bar Zn (Min): 99.999% Alloy Or Not: Non-alloy

SMM: Short Supply of Zinc Ore Likely to Ease by 2023

2021年12月10日As China's Lianyungang Port is the main storage place for imported zinc concentrates, there is a strong correlation between the import volume of zinc concentrates and the inventory at Lianyungang Port. The inflow of imported ore can be estimated by looking at the inventory changes at this port.

Zinc Ingot Slimefun/Slimefun4 Wiki GitHub

Zinc Ingots can be turned back to Zinc Dust by an Electric Ingot Pulverizer Usage Zinc Ingots are used in the following recipes: Battery GPS Teleporter Pylon Help us maintain this Wiki! This Wiki is made by the community and for the community. Here are a few ways you can help with that: Report an Issue with the Wiki

Estimation of lead and zinc emissions from mineral exploitation based

2011年11月1日Up to 2007, the cumulative productions of lead and zinc in China were estimated to be about 6.69 and 12.59 Mt, respectively; and about 1.62 Mt lead and 3.32 Mt zinc emitted into the ambient environment during the mining, processing and smelting activities, representing 24.39% and 26.36% cumulative production, respectively.

Solution Yantai Jinpeng Mining equipment, ore dressing process

It is an old cyanidation process. Firstly, add cyanide into ore to leach out minerals, then separate the solid and liquid. Add zinc powder or zinc wire into the liquid and the gold and silver will settle as gold mud via chemical reaction. The gold mud containing high gold and silver will be re-smelted to high-pure gold ingot. At present, this process as the