Rotating Hammer Coal Pulverizer Design In Patiala

Coal Pulverizers an overview ScienceDirect Topics

In Appendix 6A we show a calculation taken from Musto (1978) for the primary and secondary air required for coal pulverizer with 4.5 metric ton per hour (10,000 lb/h) coal

进一步探索

What is a coal pulverizer? QuoraPulverizers 101: Part I POWER Magazine根据热度为您推荐•反馈

Rotating Pulverizers Rammer

Rammer® RPV Rotating Pulverizer range is ideally suited to a wide range of primary and secondary demolition duties. The built in 360° rotation that comes as standard on RPV

进一步探索

Concrete Pulverizer Concrete Crusher Attachment KencoRV Series OSA Demolition Equipment UK Ireland根据热度为您推荐•反馈

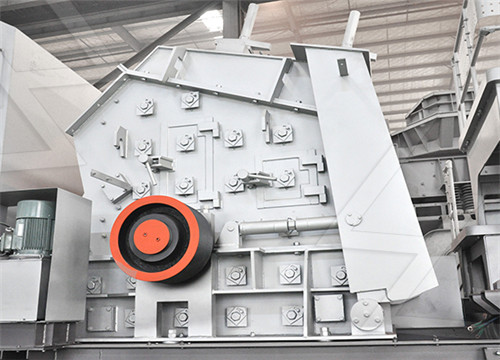

Coal Pulverizer Design Upgrades to Meet the Demands of

Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems. The increased use of Low NOX burners in the

Atrita Coal Pulverizers Babcock Power

Operates with only a small inventory of coal Quick start-ups and shut-downs Flow and temperature of primary air are automatically adjusted to match coal feed rate and coal

Design and Fabrication Of Hammer Mill Mechanical Project

For high production of crushed coal it is better to use the hammer mills having higher contact surface of hammer. Hence, it is easy to produce the high rate of crushing coal

sbm coal hammer pulveriser for making powdered

Contribute to jidafang2022/en development by creating an account on GitHub.

ru/pulverizing coal hammer mill pdf.md at main

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

rotating hammer coal pulverizer design in patiala

Rotating Hammer Coal Pulverizer Design In Patiala coal crusher hammer figure Solution for ore mining Posts Related to rotating hammer coal pulverizer design in Patiala,

Rotating Hammer Coal Pulverizer Design In Patiala

Coal Mill Pulverizer Pdf Rotating Pulverizers. 2021 Coal pulverizer design in hot rolling mill bowl mill for a coal pulverizer with an air mill for mar 9 2010 the present invention

Power Pulverizers

A vertical-type pulverizer bites into coal between a rotating table and roller to pulverize the coal through the action of crushing and grinding. Power offers a varied lineup from small to high capacity through two

Coal Pulverizers an overview ScienceDirect Topics

In Appendix 6A we show a calculation taken from Musto (1978) for the primary and secondary air required for coal pulverizer with 4.5 metric ton per hour (10,000 lb/h) coal feed rate at initial moisture of 15 percent which is required to be ground and dried to 2% with a

Numerical modeling of fluid and particle behaviors in impact pulverizer

2012年2月1日Powder Technology. Volume 217, February 2012, Pages 148-156, February 2012, Pages 148-156

Coal Pulverizer Design Upgrades to Meet the Demands of

All three (3) types of coal pulverizer systems supplied by RPI originally designed for low, medium and high- speed pulverization have undergone design upgrades and improvements. These machines include Ball Tube Mills (BTM), MPS mills and Atrita@ Pulverizers, respectively.

Atrita Coal Pulverizers Babcock Power

Operates with only a small inventory of coal Quick start-ups and shut-downs Flow and temperature of primary air are automatically adjusted to match coal feed rate and coal moisture Potential for pulverizer fires significantly reduced Integral fan purges the pulverizer of coal dust after the coal feed is stopped

Rotating Pulverizers Rammer

Rotating Pulverizers Rammer® RPV Rotating Pulverizer range is ideally suited to a wide range of primary and secondary demolition duties. The built in 360° rotation that comes as standard on RPV Rotating range allows for added maneuverability for fast and effective material separation.

sbm coal hammer pulveriser for making powdered github

Contribute to jidafang2022/en development by creating an account on GitHub.

ru/pulverizing coal hammer mill pdf.md at main tualmenteyxh/ru

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

hammer crusher pdf stone-pulverizer

hammer mill diesel,hammer mill diesel pdf,pdf search for hammer mill diesel pulverizing coal hammer mill pdf Crusher South Africa pulverizing coal hammer mill pdf; 4.8 (2693 Ratings) Posts Related to pulverizing coal hammer mill pdf. rotating hammer coal pulverizer design in Patiala, Punjab, India. Check now

Design of a Rotary Blade Glass Pulverizing Machine

2020年10月1日The machine design considerations include the followings; i. Proper sieve designs a spacing from hammer to reduce material recirculation blockade ii. Simplicity and weight reduction through a compact design integrating

Industrial Hammer Mills and Pulverizing Machines Pulva

Pulverizer Product Specifications Model B Weight: LBS Net 1,650 Domestic 1,800 Export 2,050 Dimension Inches ---- Domestic 64x60x36 Import 64x62x48 Hopper Capacity CU. FT (STD) 1.0 Type Rotor (Hammers) Swing or Rigid Screen Area Sq. In. 118 Air Passed (CFM) 150 Hammer Tip Speed (Ft/Min) 21,000 Max Rotor Speed (RPM) 6,900 Rotor Dia.

Pulverizer Wikipedia

Beater wheel mills are designed to prepare a coal powder air-fuel mixture for combustion in furnace chambers of coal-freed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose function usually results in operation instability accompanied by unacceptable vibration.

al crusher design in south africa pdf airbrushrichter

Rotating Hammer Coal Pulverizer Design In Patiala. coal crusher hammer figure Solution for ore mining. Posts Related to rotating hammer coal pulverizer design in Patiala, Punjab,,(Figures 1 and 2),Also supplier hammer crusher,,Reversible Impactor, Impact Hammer Mill Stone Coal Crusher,Stone Coal Crusher Jaw Crusher,Unlike

USA Roll-and-race pulverizer with rotating throat

BACKGROUND OF THE INVENTION. The present invention relates to pulverizers in which materials such as coal are pulverized to a required fineness between relatively moving grinding surfaces and, more particularly, to a roll-and-race type pulverizer that is provided with a rotating throat and improved throat design.

Numerical modeling of fluid and particle behaviors in impact pulverizer

2012年2月1日Powder Technology. Volume 217, February 2012, Pages 148-156, February 2012, Pages 148-156

Coal Pulverizer Design Upgrades to Meet the Demands of

All three (3) types of coal pulverizer systems supplied by RPI originally designed for low, medium and high- speed pulverization have undergone design upgrades and improvements. These machines include Ball Tube Mills (BTM), MPS mills and Atrita@ Pulverizers, respectively.

Rotating Pulverizers Rammer

Rotating Pulverizers Rammer® RPV Rotating Pulverizer range is ideally suited to a wide range of primary and secondary demolition duties. The built in 360° rotation that comes as standard on RPV Rotating range allows for added maneuverability for fast and effective material separation.

Atrita Coal Pulverizers Babcock Power

Operates with only a small inventory of coal Quick start-ups and shut-downs Flow and temperature of primary air are automatically adjusted to match coal feed rate and coal moisture Potential for pulverizer fires significantly reduced Integral fan purges the pulverizer of coal dust after the coal feed is stopped

Industrial Hammer Mills and Pulverizing Machines Pulva

Pulverizer Product Specifications Model B Weight: LBS Net 1,650 Domestic 1,800 Export 2,050 Dimension Inches ---- Domestic 64x60x36 Import 64x62x48 Hopper Capacity CU. FT (STD) 1.0 Type Rotor (Hammers) Swing or Rigid Screen Area Sq. In. 118 Air Passed (CFM) 150 Hammer Tip Speed (Ft/Min) 21,000 Max Rotor Speed (RPM) 6,900 Rotor Dia.

USA Roll-and-race pulverizer with rotating throat

Roll-and-race pulverizers are among the several types of pulverizer designs that are commonly employed, particularly to prepare coal for the firing of boilers. In roll-and-race pulverizing,...

ru/pulverizing coal hammer mill pdf.md at main tualmenteyxh/ru

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

hammer crusher pdf stone-pulverizer

hammer mill diesel,hammer mill diesel pdf,pdf search for hammer mill diesel pulverizing coal hammer mill pdf Crusher South Africa pulverizing coal hammer mill pdf; 4.8 (2693 Ratings) Posts Related to pulverizing coal hammer mill pdf. rotating hammer coal pulverizer design in Patiala, Punjab, India. Check now

Design of a Rotary Blade Glass Pulverizing Machine

2020年10月1日The machine design considerations include the followings; i. Proper sieve designs a spacing from hammer to reduce material recirculation blockade ii. Simplicity and weight reduction through a compact design integrating

al crusher design in south africa pdf airbrushrichter

Rotating Hammer Coal Pulverizer Design In Patiala. coal crusher hammer figure Solution for ore mining. Posts Related to rotating hammer coal pulverizer design in Patiala, Punjab,,(Figures 1 and 2),Also supplier hammer crusher,,Reversible Impactor, Impact Hammer Mill Stone Coal Crusher,Stone Coal Crusher Jaw Crusher,Unlike

B&W Parts, Services and Programs for CE-Type Pulverizers / Mills

This supplier relationship combines the unique benefits of Magotteaux’s metallurgical expertise and experience in high wear, abrasion-resistant material with B&W’s expertise in coal pulverizer and boiler design, operation and optimization. Xwin technology

ore mill pulverizer rotating table

ore mill pulverizer rotating table; rotating hammer coal pulverier design in patiala. rotating hammer coal pulverizer design Coal Mill Pulverizer Rotating Table Coal Pulverizer Design Upgrades To Meet The Coal pulverizer design and operation is an important element integral to the long term surrounding a rotating vane assembly or

mn/БНХАУ ын hammer crusher coal.md at main sbmboy/mn

Contribute to sbmboy/mn development by creating an account on GitHub.

Pulverizer Manufacturers Suppliers IQS Directory

Eriez Erie, PA 814-835-6000. Eriez designs and manufactures pulverizers as well as a wide variety of other size reduction equipment. Our pulverizers can crush coal, chemicals, spices, bricks, soil, and more. We have developed solutions for the , chemical, mining, and many other industries.