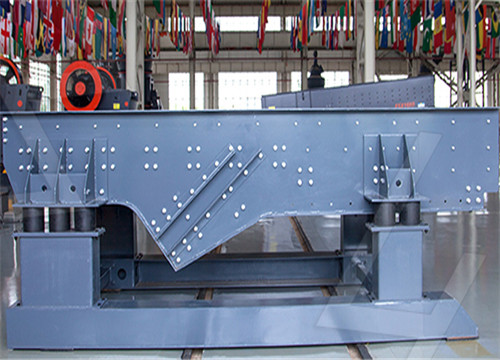

World First 100% Good Quality 2pg900x900 Double Roll Crusher Machine

Double Roll Crushers McLanahan

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1. Since each machine is custom engineered, roll elements and tooth patterns are selected depending

Double Roll Crusher, 13mm Particle Size Gilson Co.

It can reduce most rock-like materials of 0.5in (13mm) feed size to minus No. 10 (2mm) at a capacity up to 8,000lbs (3,629kg) per hour. Operates at 60Hz. Select preferred voltage of

Roll Crusher| Double Roller Crusher |DOVE

2021年6月25日DOVE Roll Crushers are designed with compact structure, small space installation, Light weight, Convenient operation, and low maintenance. DOVE Tooth Roll

Gold plant pebble crushing Henan Deya Machinery Co., Ltd.

2020年12月17日The use of a surge bin to allow full-choke feeding improves crusher performance and helps ensure that crusher components wear more evenly. Far steadier

The Differences Between Double Roll Crushers and

The Double Roll Crusher is the more cost-effective option of the two. The main differences that make up the majority of the cost differences is the drive configurations. Since the

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll

Roll Crusher Processing capacity: 5-100t/h Roller diameter: 400-700mm Feeding size: ≤25-≤100 Roller number: 2 Rotation speed: 95-180r/min Get price list We will provide you

Quality Mining Crusher MachineJaw Stone Crusher Machine

The test run of the flotation machine should meet the following requirements: the tank is filled with clean water, and the continuous operation is not less than two hours, and the

Crushers SGS United Kingdom

2022年10月31日Air Freight Packaging and Dangerous Goods Dispatch Analytical Testing for Uranium Ash Analysis Auger and Lance Sampling Biofuel Testing Calibration of

High Efficiency 2pgseries 2pg600x750 2pg900x900 2pg900x1200 Double Roll

High Efficiency 2pgseries 2pg600x750 2pg900x900 2pg900x1200 Double Roll Crusher Machine Double Roller Mill,Find Complete Details about High Efficiency 2pgseries 2pg600x750 2pg900x900 2pg900x1200 Double Roll Crusher Machine Double Roller Mill,Double Roll Crusher Machine Double Roller Mill,2pg900x900 2pg900x1200

Double Roll Crushers McLanahan

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1. Since each machine is custom engineered, roll elements and tooth patterns are selected depending on each unique application. How Double Roll Crushers Work. Operating Double Roll Crushers is quite simple. Whether it is a single or dual drive arrangement, the rolls

Roll Crushers McLanahan

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through on-site

Mid-range rolls crushers tough on any material

The Essa Rolls Crusher range includes: Essa RC2000 Rolls Crusher compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000 Rolls Crusher a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for

Roll Crusher| Double Roller Crusher |DOVE

DOVE Roll Crushers are designed with compact structure, small space installation, Light weight, Convenient operation, and low maintenance. DOVE Tooth Roll Crushers are supplied in eight models with large crushing capacity of up to 300 metric Tons/Hour.; DOVE Tooth Roller Crushers are highly safe and reliable, they are configured with high quality

Roll Crusher ManufacturerDesign Williams Crusher

Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you.

Double Roller Crusher JXSC Machine

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials. According to the number of rolls, the roll crushers can be divided

Roll crusher installation, operation and maintenance

2021年8月23日2. Maintenance of the roll crusher. (1) Roll crushers require frequent maintenance of the roll surface while in operation. (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without

Quality Mining Crusher MachineJaw Stone Crusher Machine

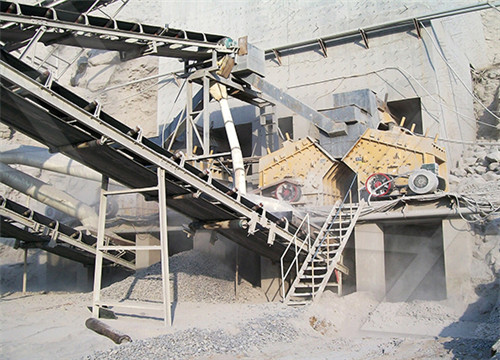

Henan Ascend MachineryEquipment Co., Ltd. was established in 2005 and it is located in the high-tech zone of Zhengzhou City, Henan Province. As a technology driven mining equipment company, it is committed to the R&D, production, sales and after-sales service of mining machinery and equipment. The company's main products are crushers

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日Roll crusher relies on its unique advantages such as less fine rate, low headroom, low horsepower, can handle materials like clay and marl with high humidity and viscosity. In addition to crushing soft to medium hardness stones such as limestone and gypsum, a hammer crusher has unparalleled advantages in breaking glass. Maintenance

Double RollTeethed Roll Crusher Mineral Processing

2016年2月24日The range of the smooth-face rolls, for example, is from about 400 ft/min for the small 12-in. rolls, to 2000-2200 feet/minute for the heavy-duty 72″ machine. The single-roll crusher has a tip speed of 400-450 ft/min while the 6- x 7-ft teethed roll crusher has a normal, no-load, surfaces speed of just under 3500 ft/min.

Zhengzhou Huahong Machinery Equipment Co., Ltd. ,Plant

Stone Production Line: mobile crushers, vertical compound crushers, roll crushers, roller crushers, impact crushers, impact crushers, hammer crushers, jaw crusher machines, efficient crushing machines, spiral stone washing machines, high efficiency sand washing machines, sixth generation sand products, hammer crushers, cone crushers and others.

Roll Crusher an overview ScienceDirect Topics

A distinct class of roll crushers is referred to as ‘sizers.’ These are more heavily constructed units with slower rotation, and direct drive of the rolls rather than belt drives. They have a lower profile, allowing material to be easily fed by loaders, and are a good choice for portable crushers at the mine that reduce the coal in size for conveying to the

Double Roll Crusher Henan Deya Machinery Co., Ltd.

2012年7月30日Double roll crusher working principle. Roll crushers, or crushing rolls, or double roll crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. They still have a useful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum

High Efficiency 2pgseries 2pg600x750 2pg900x900 2pg900x1200 Double Roll

High Efficiency 2pgseries 2pg600x750 2pg900x900 2pg900x1200 Double Roll Crusher Machine Double Roller Mill,Find Complete Details about High Efficiency 2pgseries 2pg600x750 2pg900x900 2pg900x1200 Double Roll Crusher Machine Double Roller Mill,Double Roll Crusher Machine Double Roller Mill,2pg900x900 2pg900x1200

Roll Crushers McLanahan

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through on-site

Mid-range rolls crushers tough on any material

The Essa Rolls Crusher range includes: Essa RC2000 Rolls Crusher compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000 Rolls Crusher a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for

Double Roll Crushers Astec

Double roll crushers help producers achieve the strict coal specifications they need to meet. Used as a primary or secondary unit, double roll crushers can be used in nearly any application with even the hardest, most abrasive material. This efficient crusher can lower power requirements for producing material and, with its unique features, can

Roll Crusher ManufacturerDesign Williams Crusher

Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you.

Double Roller Crusher JXSC Machine

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials. According to the number of rolls, the roll crushers can be divided

The Differences Between Double Roll Crushers and McLanahan

The Double Roll Crusher is the more cost-effective option of the two. The main differences that make up the majority of the cost differences is the drive configurations. Since the Double Roll Crusher is V-belt driven, lower motor horsepower can be used due to the flywheel design. In comparison, the DDC-Sizer is a direct drive, meaning the

Used Double Roll Crusher Machine for sale. Ascend equipment

Search for used double roll crusher machine. Find Ascend, Chieftain, and Aoerheng for sale on Machinio.

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Roll Crusher New or Used Roll Crusher for sale Australia

There are 3 Roll Crusher for sale in Australia from which to choose. Overall 100% of Roll Crusher buyers enquire on only used listings, 0% on new and 2.33% on both new and used Roll Crusher items. Buyers usually enquire on 1.98 different Roll Crusher classifieds before organising finance. Roll Crusher are listed between $9,500 and $125,000

Used Crushers for Sale Mining | Surplus Record

2" x 12" Glebar #PG-9CRG, crush roll grinder, outside dimension, HMI touch screen. Category: Crushers. Seller: TNT Industrial. Location: Orange, CA. Mfr: Glebar. Model: PG-9CRG. Find many great newused options and get the best deals for 2" x 12" Glebar PG-9CRG Crush Roll Grinder Cyclindrical OD at the best online prices at eBay! Free

2PGC-400x250 Artificial Double Roll Crusher for Stone Crushing

2.With sensor, the machine can load relief when overload, so that to protect the machine. 3.The advanced hard faced technology improves the roller covers' life. 4.Good performance, low cost in operation and easily maintenance. Main parameters of teeth roll crusher

MS Roll Crusher Double Roll Crusher Manufacturer from Indore

Pioneers in the industry, we offer double roll crusher from India. Double Roll Crusher REQUEST CALLBACK +1 Get Best Quote Approx. Rs 15 Lakh / Piece Get Latest Price Product Brochure Product Details: Roller Crusher Machine Production Capacity 25 tph. Yes! I am interested Looking for MS Roll Crusher ? X Contact Us Quickly Explore More