The Major Steps Of Mining Iron

Iron processing Definition, History, Steps, Uses,Facts

When iron making was properly established, two types of furnace came into use. Bowl furnaces were constructed by digging a small hole in the ground and arranging for air from a bellows to be introduced through a pipe or

Iron Mining Process Minnesota Iron

The iron ore is separated from the taconite using magnetism. The remaining rock is waste material and is dumped into tailings basins. The taconite powder with the iron in it is called concentrate. Pellets The concentrate

Iron ore Wikipedia

OverviewExtractionSourcesMine tailingsProduction and consumptionAbundance by countrySmeltingSee also

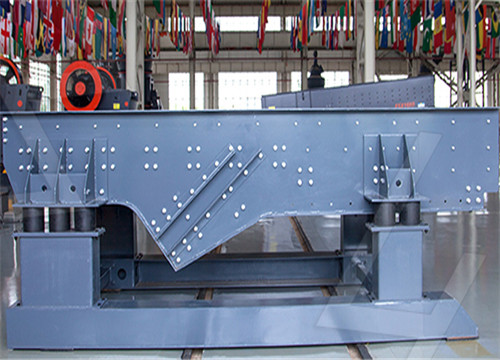

Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, high-quality fine ore powders, are known as fines. Magnetite is magnetic, and hence easily separated from the gangue minerals and capable of prod

进一步探索

Different Types of Iron Ore Mineral ProcessingMetallurgyWhat is Iron Ore used for?根据热度为您推荐•反馈

Sintering: A Step Between Mining Iron Ore and Steelmaking

2019年6月11日It’s a major ingredient in steel. According to the latest USGS Iron Ore report: In 2018, mines in Michigan and Minnesota

Iron processing Ores Britannica

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by

Iron mining in the United States Wikipedia

In common with other commodities, the history of iron mining in the United States includes a shift to larger but lower-grade ore deposits, a shift from underground to open-pit

Iron Ore Mining Techniques Metal Extraction

The steps need the ore to be concentrated first, followed by the extraction of the metal from the concentrated ore after which the metal is purified. How is iron extracted from its ore? Iron is concentrated by the process of

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

The Step-by-Step Process of Producing Iron from Iron Ore

2017年10月23日The Separation Of Iron- The molten iron that settles down at the bottom of the furnace contains impurities and rocks that combine with the limestone to create slag. This slag, being lighter, floats

What is the major step in the process of open-pit and

2023年3月10日Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3.

Sintering: A Step Between Mining Iron Ore and

2019年6月11日It’s a major ingredient in steel. According to the latest USGS Iron Ore report: In 2018, mines in Michigan and Minnesota shipped 98% of the usable iron ore products in the United States with an

Iron ore Wikipedia

The two main methods of recycling iron from iron ore tailings are magnetizing roasting and direct reduction. Magnetizing roasting uses temperatures between 700 and 900 °C for a time of under 1 hour to

Iron Ore Statistics and Information U.S. Geological Survey

Iron ore is the source of primary iron for the world's iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries. The seven largest of these producing countries

Iron processing Ores Britannica

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red;

Steel Production American Iron and Steel Institute

Steel Production Steel Flowlines How Steel Is Made Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides.

The six main steps of iron ore processing Multotec

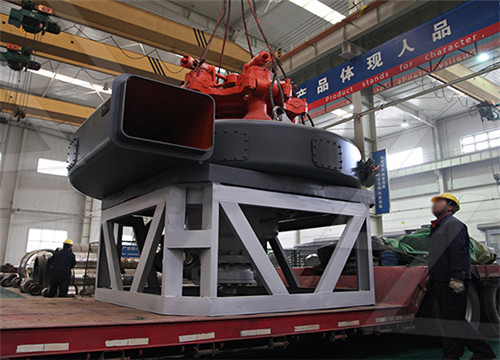

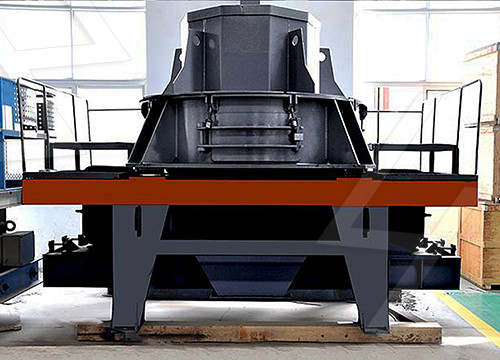

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Iron Ore Mining Techniques Metal Extraction

The steps need the ore to be concentrated first, followed by the extraction of the metal from the concentrated ore after which the metal is purified. How is iron extracted from its ore? Iron is concentrated by the process of

The mining value chain: A hidden gem McKinsey

2020年10月5日Mining value chains also face pressure from recent shifts in commodity markets (strong price fluctuations, shrinking value pools, changing market structures with new entrants, and tightened regulations)

Understanding Iron Ores and Mining of Iron Ore

2015年4月3日Fig 1 Steps in open pit mining of iron ore Environmental issues Materials generated as a result of open-pit mining include overburden, waste rock, and mine water. Other wastes may include

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

Top five iron ore producing companies in 2020 by

2021年5月10日Top five largest iron ore producing companies in the world in 2020. 1. Vale 300 million tonnes. Brazilian miner Vale was the world’s top producer of iron ore in 2020, with an output totalling just over 300

The Environmental Problems Caused by Mining Earth.Org

2022年4月3日For example, mining a kilogram of diamond produces around 800,000 kg CO 2 e compared to a kilogram of a highly abundant mineral such as iron which produces only about 2 kg CO 2 e. The creation of products from mined materials uses high amounts of energy throughout the different stages of the production chain and most of this energy is

Making steel ArcelorMittal

Making steel. Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature. The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic oxygen furnace route, and the electric arc furnace route. Both processes are being continually improved

From Ore to Finished Product Copper

Copper ore is extracted using two basic methods of mining open pit or underground mining. 3. Processing of Copper Ore The first step in processing the ore removed from the mine is to break the large rocks of ore into smaller pieces. This is accomplished by a variety of subsequent processing steps. 4. Beneficiation of Copper Ore

Iron ore Wikipedia

The two main methods of recycling iron from iron ore tailings are magnetizing roasting and direct reduction. Magnetizing roasting uses temperatures between 700 and 900 °C for a time of under 1 hour to

Iron Ore Statistics and Information U.S. Geological Survey

Iron ore is the source of primary iron for the world's iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries. The seven largest of these producing countries

Sintering: A Step Between Mining Iron Ore and

2019年6月11日It’s a major ingredient in steel. According to the latest USGS Iron Ore report: In 2018, mines in Michigan and Minnesota shipped 98% of the usable iron ore products in the United States with an

Iron processing Ores Britannica

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red;

Steel Production American Iron and Steel Institute

Steel Production Steel Flowlines How Steel Is Made Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Iron mining in the United States Wikipedia

Iron mining in the United States produced 48 million metric tons of iron ore in 2019. [1] Iron ore was the third-highest-value metal mined in the United States, after gold and copper. [2] Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and Utah. Most of the iron ore was mined in northern

Understanding Iron Ores and Mining of Iron Ore

2015年4月3日Fig 1 Steps in open pit mining of iron ore Environmental issues Materials generated as a result of open-pit mining include overburden, waste rock, and mine water. Other wastes may include

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

sbm/sbm the major steps in the process of mining iron.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Top five iron ore producing companies in 2020 by

2021年5月10日Top five largest iron ore producing companies in the world in 2020. 1. Vale 300 million tonnes. Brazilian miner Vale was the world’s top producer of iron ore in 2020, with an output totalling just over 300

The Environmental Problems Caused by Mining Earth.Org

2022年4月3日For example, mining a kilogram of diamond produces around 800,000 kg CO 2 e compared to a kilogram of a highly abundant mineral such as iron which produces only about 2 kg CO 2 e. The creation of products from mined materials uses high amounts of energy throughout the different stages of the production chain and most of this energy is

Making steel ArcelorMittal

Making steel. Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature. The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic oxygen furnace route, and the electric arc furnace route. Both processes are being continually improved

Extraction of Metals Methods of Extraction of Metals from

The steps involved are either calcination or roasting and then heating with a reducing agent. Purification of the metal Here the metal is purified for practical purposes. Aluminium: Bauxite AlO x (OH) 3-2x [where 0 < x < 1] Kaolinite (a form of clay) [Al 2 (OH) 4 Si 2 O 5] Iron: Haematite Fe 2 O 3 Magnetite Fe 3 O 4 Siderite FeCO 3